- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

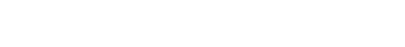

Rolling Mortar Wall

Processing Capacity:~

Feed Particle Size:~

Applicable Materials:River pebbles, granite, basalt, iron ore, limestone, quartz stone, diabase, iron ore, gold ore, copper ore, etc.

Application Scope:Sand and gravel yard, concrete mixing station, dry mortar, power plant desulfurization, quartz sand, etc.

- +8613503852957

- 7 * 24-hour Service Hotline

The rolling mortar wall and the crushing wall are the main components in the cone crusher. The rolling mortar wall is also called a fixed cone because it is fixed. The crushing wall moves evenly back and forth, so it is called a moving cone. When the cone crusher is running, the crushing wall and the rolling mortar wall are sometimes close and sometimes far away, and the components crush the material, so it is discharged from the discharge port. There are U-shaped screws on the rolling mortar wall to hold the adjusting ring. Their working parts are compositely inlaid with carbide or carbide, so that the wear surface of the bimetallic composite wear-resistant parts has excellent wear resistance, the wear degree of the wear-resistant parts is improved, and the service life is also extended.

Advantages And Characteristics

1. The new composite rolling mortar wall adopts bimetal composite wear-resistant parts, which has twice the life of traditional parts.

2. High wear resistance, the new double gold composite wear-resistant parts can adapt to harsh industrial and mining conditions and highly corrosive environments.

3. High cost performance. The cost of using new bimetal composite wear-resistant parts is reduced, which improves customer benefits.

4. Wide range of applications. The new bimetal composite wear-resistant equipment is suitable for crushing iron ore, non-ferrous metals, bluestone, granite, and cobblestones (river pebbles).

5. Strong technological and technical capabilities. Zhongyi Mining Machinery’s new rolling mortar wall bimetallic composite wear parts have their own technological characteristics.

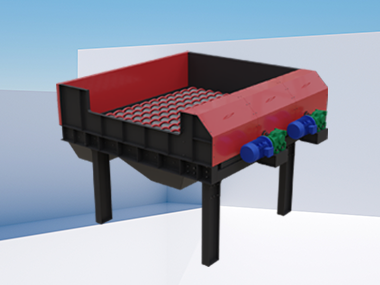

Recommended Products

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)