- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

Hammerhead

Processing Capacity:~

Feed Particle Size:~

Applicable Materials:Granite, basalt, quartzite, marble…

Application Scope:Wear-resistant parts of hammer crusher equipment

- +8613503852957

- 7 * 24-hour Service Hotline

The hammer head is an important working part of the hammer crusher equipment. Among them, the quality, shape and material of the hammer head determine the production capacity of the crusher equipment. Therefore, the power of the hammer head is directly proportional to the weight of the hammer head. The heavier the weight, the higher the output. According to the customer's needs and output configuration, the corresponding hammer head can be customized for the customer. Only the hammer head has a new type of polymer element high-strength steel composite casting, and its service life is Several times that of a general hammer head.

Advantages And Characteristics

The alloy and the hammer head are cast into a "high wear-resistant alloy hammer head" and undergo modification treatment to greatly refine the grains. The main feature of the wear-resistant composite alloy hammer head is that the ultra-high wear-resistant alloy is embedded in the working part, thus The wear resistance of the hammer head is greatly improved. High-quality hammer head wear-resistant parts are a high-wear-resistant hammer head developed to deal with the serious reduction in the life of the hammer head caused by the high SiO2 content in the stone or the large crystal size that is difficult to break. When the wear-resistant hammer head is subjected to severe impact and Significant work hardening occurs during friction, which is beneficial to improving wear resistance while the center part still maintains low hardness and good toughness. The crushing efficiency is increased by more than 30%. The high wear-resistant alloy hammer head is widely used in various crushing industries such as coke, coal, coal gangue, metallurgy, glass, mining ore, cement plant limestone, clinker, brick factory leaf rock, etc.

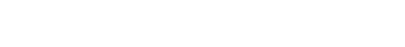

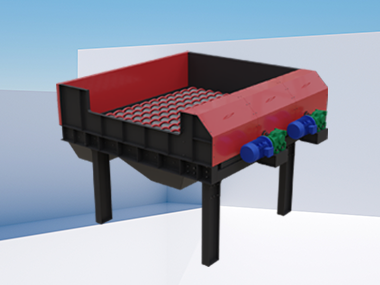

Recommended Products

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)