- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

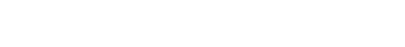

Crawler-type Construction Waste Crushing And Screening Station

Processing Capacity:70-280t/h

Feed Particle Size:≤800mm

Applicable Materials:Waste construction waste reinforced concrete, cement pile heads, discarded red bricks, limestone, river pebbles...

Application Scope:Urban construction waste treatment, municipal engineering road reconstruction and expansion, sand and gravel plants...

- +8613503852957

- 7 * 24-hour Service Hotline

Professional manufacturer of crawler-type construction waste treatment equipment

This series of crawler mobile crushing stations are mainly used for crushing construction waste, rocks, ores, old asphalt concrete blocks and other materials on roads. They adopt new environmentally friendly crushing technology, use both oil and electricity, and are fully functional. Compared with the same model, it has higher output and lower energy consumption. It adopts a dust-free system to control dust pollution from the source. It has fewer restrictions on environmental conditions and enables free operation in different locations.

Crawler mobile crushing station turns construction waste into treasure

Test run of crawler mobile impact crusher completed

Crawler mobile crushing station

Crawler mobile impact crusher

Crawler mobile gravel crusher

Zhongyi crawler-type construction waste crushing machine is sent to Xi'an, Shaanxi

New and efficient crawler-type mobile construction waste treatment equipment has been installed

Fully automatic hydraulic driven crawler mobile crushing and screening station equipment

Crawler type mobile construction waste crusher test run

The technology and quality inspection department is conducting acceptance inspection of the crawler mobile crushing station

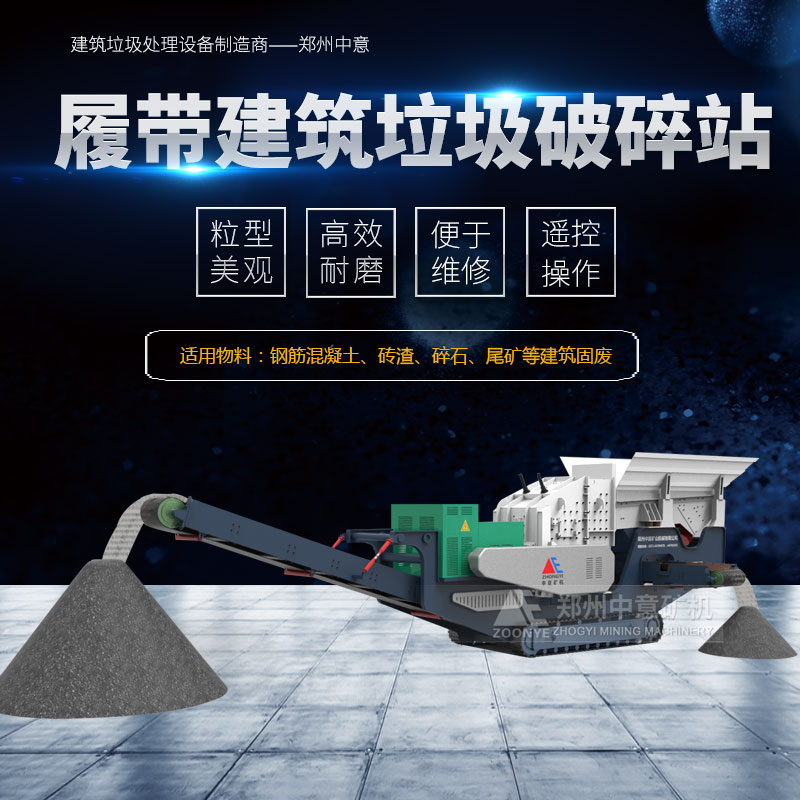

Advantages And Characteristics

Advantages of crawler mobile construction waste crusher

1. Dual use of oil and electricity, flexible switching, reducing costs;

2. Completely separate reinforced concrete to avoid clogging of the crusher;

3. The chassis adopts an all-steel ship-shaped structure, which has high strength, strong adaptability to the working site, and stable operation;

4. It adopts a high-power traveling motor with strong horsepower, safe and reliable production operation, and simple operation and maintenance;

5. Use high-quality motors to achieve strong power system performance, with notable features such as low noise and energy saving;

6. The design of the whole machine is scientific and reasonable, and the comprehensive performance has been further optimized. With excellent quality, its performance can be fully exerted;

Working Principle

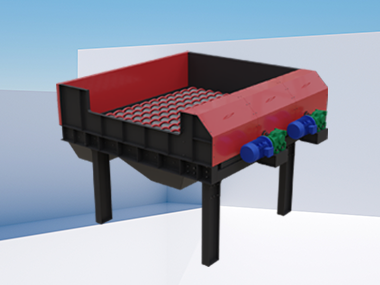

The raw materials are sent into the silo through forklifts, excavators and other equipment. The materials in the silo enter the screening feeder. The part of the raw materials with the required particle size leaks from the sieve holes and then directly forms a mound through the excavating belt conveyor. ; Larger materials enter the new construction waste crusher through the screening feeder for crushing, and then when the particle size reaches the standard, they are discharged from the discharge port into the vibrating unloader; the unloader sends the materials evenly into the main unloader. Material belt conveyor, the belt conveyor transports the materials out to form a material pile; at the same time, an iron remover is installed above the main discharge belt, and the iron in the materials is separated after being attracted by the iron remover.

Crawler-type mobile crushing and screening station shipped from Zhongyi to Australia

Mr. Tang from Lijiang, Yunnan purchased Zhongyi CP series crawler-type mobile crushing and screening station

Shaanxi Phoenix Panni Construction Waste Recycling Company purchased CP series crawler mobile crushing and screening station

Guangdong construction waste treatment project introduces Sino-Italian crawler crushing station

Technical Parameter

| name | CPGF1011 | CPGF1311 | CPGF1313 | CPGF1315 |

| Silo | Overall steel structure | Overall steel structure | Foldable steel structure | Foldable steel structure |

| feeding machine | GZT1038 | GZT1338 | GZT1248 | GTZ1248 |

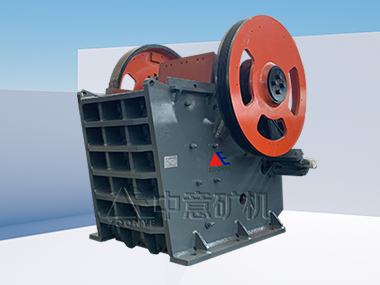

| Impact Crusher | PFW1110 | PFW1113 | PFW1313 | PFW1315 |

| Maximum feed particle size(mm) | 700 | 700 | 800 | 800 |

| production capacity(t/h) | 70-120 | 80-150 | 100-220 | 100-280 |

| Discharge belt conveyor | B800 | B1000 | B1200 | B1200 |

| Unearthed belt conveyor | B500 | B500 | B500 | B500 |

| Hydraulic assembly | YC20 | YC20 | YC30 | YC30 |

| Track assembly | T30 | T40 | T40 | T40 |

| Generator set | 250GF | 300GF | 500GF | 500GF |

CP系列履带式建筑垃圾筛分站技术参数:

| Model | CPGS150 | CPGS180 | CPGS210 |

| Silo | Overall steel structure | Overall steel structure | Overall steel structure |

| Feeding belt conveyor | B800 | B1000 | B1200 |

| Circular vibrating screen | 3YA1548 | 3YA1854 | 3YA2160 |

| Processing capacity (t/h) | 50-200 | 100-300 | 150-400 |

| Feeding belt conveyor | B800 | B1000 | B1200 |

| Screen belt conveyor | B800 | B800 | B1200 |

| Three types of discharging belt conveyors | B500 | B650 | B650 |

| Hydraulic system | YC20 | YC20 | YC30 |

| Track assembly | T30 | T30 | T40 |

| Generator set | 150GF | 150GF | 150GF |

Recommended Products

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)