- Factory Direct Sale

- Quality Assurance

- Quick Response

- Service Without Worry

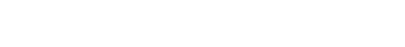

GFXC Series Comprehensive Air Separator

Processing Capacity:30-150m³/h

Feed Particle Size:≤80mm

Applicable Materials:Construction waste, decoration waste, old waste, etc.

Application Scope:Separation of light materials from decoration waste and construction waste

- +8613503852957

- 7 * 24-hour Service Hotline

Construction waste is a resource that can be utilized. After being crushed and screened, the waste materials such as bricks, stones, and concrete can be used as sand substitutes for masonry mortar, plastering mortar, concrete cushion, etc. Used in the production of building materials products such as blocks, paving bricks, and checkered bricks. However, construction waste is often mixed with plastics, cloth, waste paper, packaging waste, film and other light materials. If it cannot be sorted effectively, it will directly affect the recycling rate of construction waste. In order to change this situation, Zhengzhou Zhongyi Mining Machinery has developed a new type of construction waste lightweight material processor GFXC series comprehensive air separator. It has good light material separation effect and is another innovation in the field of construction waste recycling.

Construction Waste Light Material Treatment Effect

The GFXC series comprehensive air separator is mainly used to separate light materials (such as paper, plastic bags, films, etc.) from heavy materials in construction waste. That is, based on the principle of aerodynamics, it separates light and heavy materials according to their different densities. To achieve the cleanliness of construction waste aggregates. The comprehensive air separator developed by our company has the advantages of low power, low noise, large processing capacity, high efficiency, and good sorting effect. It can be widely used in large-scale treatment of large and medium-sized construction waste treatment plants.

Advantages Of Construction Waste Light Material Processor

1. Circulating air design: reduce dust and improve equipment efficiency;

2. The impurity removal rate is high at one time and can be connected in multiple stages to ensure the impurity removal effect to a large extent.

3. Double fans and variable frequency motor design, more environmentally friendly and energy-saving

4. Frequency conversion control. The air volume, wind speed and wind pressure at the fan outlet can be controlled by the frequency converter.

5. Easy maintenance and low motor consumption.

Construction Waste Light Material Separator

Light Material Separation Equipment

Light Material Sorting Machine

Working Principle

The new construction waste light material processor uses cyclone airflow classification technology to feed the waste at a balanced rate and enter the airflow classification separation chamber through the feeding roller. Then the dust and light substances such as paper, plastic, wood chips, etc. are separated under the action of strong air flow. The dust and light substances are directly introduced into the settling chamber to be separated from the finished materials. The separated dust and light substances are separated from the other part of the separator. The outlet is discharged to achieve the cleanliness of construction waste aggregates.

Technical Parameter

| Model | Power(kw) | Throughput(m³/h) |

| GFXA800 | 11-18.5 | 30-80 |

| GFXA1000 | 15-22 | 50-100 |

| GFXA1200 | 15-30 | 60-150 |

Customized Service Process

You can also contact us for more models and support customization

-

Consulting Customer Service

You only need one phone call,

Consult now

leave the rest to us -

Understand Requirements

Sales team to talk to you in detail.

Provide Requirements

Tell us about your needs -

Planning And Design

Professional engineers provide reasonable solutions

Get the solution

based on your needs -

Production-Manufacturing

We will complete the quality

Scheduled equipment

within a reasonable time -

Technical Installation

Technical installation professional installation team on-site installation

Technical support

Debugging to stable production -

Late Maintenance

If you have any questions in the later stage,

Contact Us

you can contact the after-sales engineer

- 200000+

- Favorite Choice For Home Customers

Zhongyi Machinery has won worldwide acclaim with its good reputation, excellent quality, and sound after-sales service, shining brightly in numerous domestic and foreign enterprises!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)